The future of the strobel industry: innovations and advancements shaping the industry

The strobel industry has witnessed significant growth and advancements in recent years, fueled by the ever-increasing demand for precision machining and manufacturing processes. This sector plays a crucial role in various industries, such as automotive, aerospace, electronics, and medical devices. As the demand for quality products continues to soar, manufacturers in the strobel industry are constantly seeking innovations and advancements to meet these evolving needs. One such innovation that holds immense potential is Zerspanung.

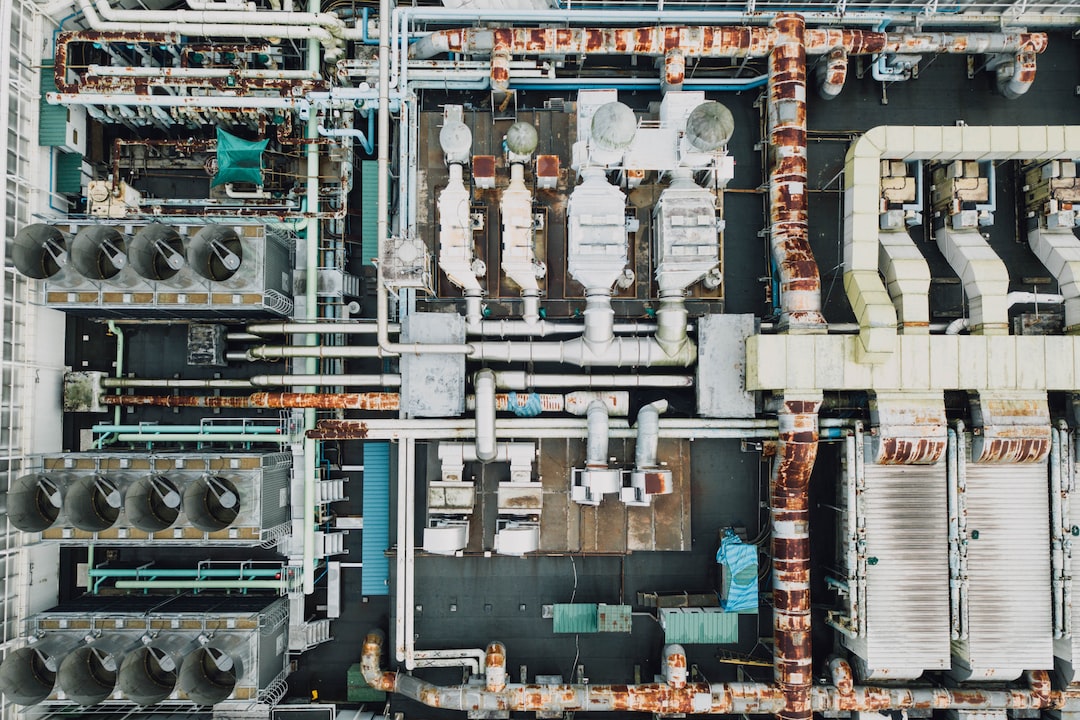

Zerspanung, a German term that translates to “machining,” refers to the technique of cutting and shaping materials using specialized tools and machines. This process involves removing excess material from a workpiece, creating precision components with desired dimensions and specifications. The utilization of Zerspanung techniques in the strobel industry has proven to be a game-changer.

One of the primary reasons why Zerspanung has gained immense popularity in the strobel industry is its ability to enhance efficiency and productivity. With the advancement of automation technologies, manufacturers are now able to maximize the potential of Zerspanung by integrating it with robotic systems. This integration facilitates the automation of machining processes, allowing for faster and more precise production. Furthermore, the use of advanced cutting tools and computer numerical control (CNC) machines has revolutionized the strobel industry by enabling intricate designs and complex machining operations.

Another significant aspect of Zerspanung is its contribution to sustainability and waste reduction in the strobel industry. Traditional machining processes often produce a significant amount of waste material, leading to environmental concerns and increased costs. However, Zerspanung techniques, such as high-speed machining and precision machining, minimize material waste by optimizing the cutting parameters and reducing excessive cuttings. This not only contributes to eco-friendly manufacturing practices but also helps manufacturers reduce costs associated with material waste and disposal.

Moreover, Zerspanung has enabled the strobel industry to achieve higher levels of precision and accuracy. The integration of advanced computer-aided design (CAD) software with CNC machines allows manufacturers to create highly detailed and intricate components with consistent quality. This level of precision is crucial in industries where the smallest deviation can lead to catastrophic consequences, such as aerospace and medical devices.

Looking ahead, the future of the strobel industry lies in the continued advancements and innovations in the field of Zerspanung. Manufacturers are investing heavily in research and development to further enhance the capabilities of this technique. For instance, the use of artificial intelligence (AI) and machine learning algorithms in Zerspanung is gaining traction, enabling machines to learn from previous machining operations and optimize future processes automatically.

In conclusion, the strobel industry is witnessing significant transformations and advancements, with Zerspanung playing a vital role in shaping its future. From increased efficiency and productivity to sustainability and precision, the integration of Zerspanung techniques is revolutionizing the manufacturing processes in this industry. As technology continues to evolve, it is anticipated that Zerspanung will continue to drive innovation and propel the strobel industry into a new era of efficiency, sustainability, and precision manufacturing.

For more information visit:

Zerspanung | Lohnfertigung | Strobel Industry

https://www.strobel-industry.de/

Unlock the future of innovation with Strobel Industry’s cutting-edge solutions. Revolutionize your business with our game-changing technology and unparalleled expertise. Stay tuned for the launch of strobel-industry.de – the gateway to endless possibilities.